With the current media attention on the rapidly increasing gas and electricity bills, we felt it was worth putting together a short series of articles on how to reduce your energy bills arising from your compressed air system.

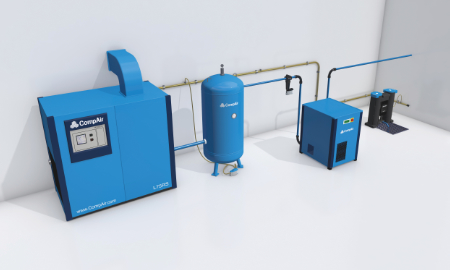

Compressed air is a vital part of any manufacturing facility, but since the compressor tends to be stuck away at the back of the factory it is generally one of the last things people think about when it comes to energy saving or indeed energy costs.

It is a little recognised fact that almost 10% of the UK’s total industrial electricity usage is for air compressors. Even a small factory or workshop will have a 7.5KW or 11KW air compressor. With currently rocketing electricity prices these machines will cost in the region of £2.50 per hour to run in electricity costs. (11KW @ 25p / KWhr = £2.5). Multiplied by 8 hours a day 5 days a week this equates to around £6,000 per year in electricity alone.

If your total compressor size is 5 or 10 times this you can see the scale of the price you may be paying.