Excellent Company to Work With...Excellent company to work with. Staff very helpful and pleasant. Many successful compressed air installations and service work completed on schedule with only praise from our MOD client. Recommenda...

Lubricated screw compressors are the most common type of industrial air compressor in the market today. Screw compressors are probably not the biggest selling type of air compressor in terms of units sold, this title will be held by the many small piston machines sold. But for anything over 2 or 3 kW in size and used for real industrial / factory applications the biggest selling will be the lubricated screw machine.

Lubricated screw compressors hold this position since they are reliable, highly efficient, low noise, small footprint and are available in a range of sizes and configurations. As technology has improved they have become more efficient. Modern variable speed lubricated screw compressors can use over 30% less energy than an equivalent fixed speed unit. With advances in electronics, control systems have made managing multiple screw compressors automatically much more achievable and efficient. Modern controllers can select the most efficient compressor(s) to meet current factory demand, selecting fixed or variable speed machines depending on circumstances. All of this has improved overall system efficiency and minimised energy costs whilst still producing the exact amount of compressed air you need.

The lubricated screw machine creates compressed air in the ‘air end’. The air end consists of two ‘screws’ or ‘rotors’ within a housing. The rotors and housing are complex shapes, that interact with each other in an extremely precise way. All these components are machined to extremely tight tolerances, whilst also being robust enough absorb huge amounts of energy and very high temperatures. A screw compressor air end has a tough life!

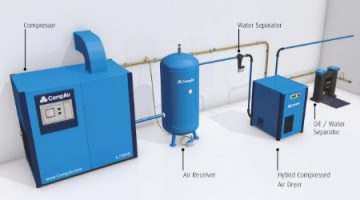

To help lubricate, cool and seal the moving parts within the air end, special oil or ‘coolant’ is injected into the rotating air end. The coolant also has a tough life. Its role is not just to lubricate but also has to withstand the high temperatures created by the compression process and carry this heat away from the air end. It also picks up water, which comes out of the compressed air, and carries this away too. The coolant is then spun to separate it from the compressed air, filtered to remove water and contaminants and the cooled before being injected back into the air end. No wonder the coolant needs to be a specialist screw compressor, high specification grade of oil.

Lubricated screw compressors come in a range of sizes ranging from 5 to 250kW motor power. The bigger the power the more compressed air the compressor makes. CompAir make one of the most efficient, reliable and smallest footprint range of compressors on the market today the L series. For more information on the L series click here.

Screw compressors are normally mounted within a rectangular body or housing. The housing is designed to ensure cooling airflow is adequate for the size of compressor and to ensure all components within the compressor receive adequate cooling. Note: sometimes in hot weather you see people removing the panels from the compressor to help cool it. DON’T DO THIS, this will make the cooling less effective and put the compressor at risk of overheating.

Smaller compressors up to maybe 30kW in size can often be mounted on an air receiver and also have an integral dryer so that the complete compressor package can be picked up and moved as one. This has the benefit of simplifying installation, requiring only to be connected to a power supply and pipework system, and reduces the overall footprint of the compressor. The CompAir air compressors of this design are called ‘Air Centres’.

Excellent Company to Work With...Excellent company to work with. Staff very helpful and pleasant. Many successful compressed air installations and service work completed on schedule with only praise from our MOD client. Recommenda...

Lubricated Screw compressors

High quality brands from a company you can trust

The technology and systems used in the compressed air industry is constantly changing. Air Equipment work with many of the companies that are leading this development. Because of our close co-operation with these world leading companies we are able to pass on these new technologies to you.

Learn about usSign up to the free newsletter and receive our monthly bulletin.