‘In 29 years on the job I have always dealt with Air Equipment’...'In 29 years on the job I have always dealt with Air Equipment. They offer a professional service and will always do their best to attend in a breakdown/emergency situatio...

Air Equipment is a distributor for Elmo Rietschle vacuum pumps and low pressure blowers. Elmo Rietschle supply a wide range of different pumps all of which are designed to meet specific requirements of either vacuum or low pressure compressed air. Usually the same technology can provide both negative and positive pressures. The most appropriate pump for your application will depend on exact requirements for vacuum or positive pressure and hours run.

In the UK the most common technology used for the pumps are

The technology and operating principle of these types are outlined below

Some technologies are so good that it is hard to improve them. The Elmo Rietschle Side channel blowers are such an example. Performing flawlessly day in and day out with virtually no downtime, the G-Series has a proven history of outstanding reliability over many decades of service.

We offer side channel blowers in a wide variety of performance ranges to cover the most varied requirements, up to 3,000 m³/h and differential pressures of up to 1,000 mbar.

How does a side channel blower work?

The G-Series impeller is mounted directly on the motor shaft for contact free compression. Maximum operational reliability, even at high differential pressures, is ensured by the arrangement of the bearings outside the compression chamber.

The gas is taken in through the inlet. As it enters the side channel, the rotating impeller imparts velocity to the gas in the direction of rotation. Centrifugal force in the impeller blades accelerates the gas outward and the pressure increases.

Every rotation adds kinetic energy, resulting in further increase of pressure along the side channel. The side channel narrows at the rotor, sweeping the gas off the impeller blades and discharging it through the outlet silencer where it exits the pump.

Our leading industrial dry running and oil lubricated rotary vane pumps cater for a wide performance range. The eco-friendly dry running rotary vane pumps are used for industrial vacuum, pressure and combined pressure and vacuum applications. Whilst, the time-tested oil lubricated rotary vane machines are typically used for generating vacuum.

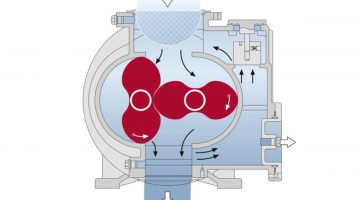

The C-Series dry claw vacuum pumps and claw air compressors of Elmo Rietschle generate contact-free vacuum or compressed air efficiently and economically. This is possible because of the principle of internal compression in the rotary claw design. The gas is pre-compressed within the compressing chamber and is then discharged.

The Elmo Rietschle dry claw pumps offer significant energy saving and high efficiency compared to the traditional rotary lobe blower designs without internal compression.

The claws of the C-Series feature an optimized, high precision shape and roll together without contact, synchronised by a precision gear set. The compression is achieved dry and wear free. Special seals separate the compression chamber and gearbox. The claw rotors control the transportation of the medium by opening and closing the inlet and outlet channels. Thus no sealing fluid within the compression chamber is needed.

Explosion proof versions with reduced leakage are available as well as ATEX compliant vacuum pumps and compressors.

‘In 29 years on the job I have always dealt with Air Equipment’...'In 29 years on the job I have always dealt with Air Equipment. They offer a professional service and will always do their best to attend in a breakdown/emergency situatio...

Vacuum pumps

Professional support when you need it

Air Equipment can support you and your compressed air system throughout its life. We will monitor your system to ensure it remains reliable, efficient and operating correctly. We will service your compressors, filters and air dryers to schedule, to ensure they continue to operate correctly. We can also help and guide you through changes to your air system as your company changes and grows.

Learn about usSign up to the free newsletter and receive our monthly bulletin.