Very happy with the service...'Very happy with the service but due to the busy workload of our workshop did not get adequate time to talk to your engineers, hence all the no answers, this was no fault of your engineers'...

The quality of compressed air used in the food industry is of upmost importance as even the slightest traces of contamination can result in altered or polluted product batches and the risk of hazards for consumers.

To ensure best practice, the International Standards Organisation (ISO) established a new class of air quality for sensitive industries such as food and beverage. Known as Class 0, it is the most stringent air quality class, limiting oil contamination in liquids, aerosols and vapours.

Class zero air quality is easily achieved by the latest range of CompAir oil free compressors. The CompAir oil free product range covers compressors from 7.5 KW up to over 250KW across four different product lines including

all of the compressors across these ranges achieve class zero air quality as well as offering unique benefits in terms of efficiency, durability and reliability.

Find out more bout the CompAir oil free range of compressors here

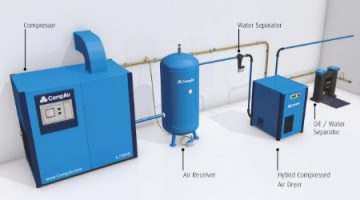

Compressed air purification equipment is essential in the food and beverage industry where air purity and integrity of product is essential. It must deliver uncompromising performance and reliability with the right balance of air quality and cost of operation.

Air Equipment can offer a comprehensive range of purification equipment available to exactly match your requirements, ensuring both initial capital and operational costs are kept to a minimum. These products include:

Filters

Water Separators

Adsorption dryers

Refrigerated dryers

Independent of any type of compressor, there are 4 main sources of contamination to be found in a compressed air system which need to be purified to protect products and processes:

Water vapour, condensed water and water aerosols

Atmospheric dirt

Micro organisms

Rust and pipe corrosion

There are specific air treatment products that can take out each of these types of contaminant. These range from desiccant and refrigerant dryers to filters with specific media to target specific impurities.

Fore more information on any of the items discussed above contact us

Very happy with the service...'Very happy with the service but due to the busy workload of our workshop did not get adequate time to talk to your engineers, hence all the no answers, this was no fault of your engineers'...

Air Compressors from a company you can trust for best practice

The technology and systems used in the compressed air industry is constantly changing. Air Equipment work with many of the companies that are leading this development. Because of our close co-operation with these world leading companies we are able to pass on these new technologies to you.

Learn about usSign up to the free newsletter and receive our monthly bulletin.