Always Provide a Professional Service...5 Star Rating Always provide a professional service for planned visits and the response time on call outs and breakdowns is superb. Recommendation from a customer in Bedfordshire...

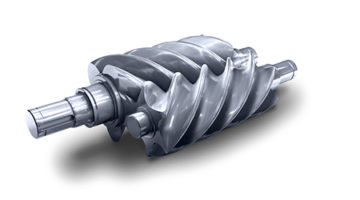

Traditionally air compressors are fixed speed so they run at a fixed and consistent speed, which produces a fixed amount of compressed air per minute. This is great if you are using this exact amount of compressed air since the air compressor is constantly running at its most efficient point.

However, as we all know, this is never the case in the real world. The air compressor tends to run to fill up the receiver tank and to supply enough air for the current usage, it then stops running as the required compressed air is drawn off the receiver tank. A few minutes to a few tens of minutes later the air has been drawn off the receiver to the point that the compressor has to start up again to pump the system back up to working pressure and so it goes on through the day.

Read more about the benefits of variable speed compressors here

Since large electric motors aren’t designed to start up frequently, due to the stresses that a start-up puts through the motor, air compressors are designed to ‘run on’ in an ‘unloaded’ condition for a few minutes after the system air pressure has been reached. When unloaded, a compressor is still turning but by shutting a few valves within the compressor no compressed air is being made. If more air is required when a compressor is running in an unloaded state it is simply a case of opening the valves again to start making compressed air again.

The downside of running in an unloaded condition is that the air compressor is still using between 25% and 50% of the energy it is using when creating compressed air. This energy is totally wasted just keeping the compressor turning over.

If a fixed speed air compressor is running at 50% load and has a run on of 5 minutes. It will run for say 10 minutes at full power, then 5 minutes unloaded. It will then stop. 5 minutes later it will restart and run for a further 10 minutes followed by a further 5 minutes unloaded and so on. As you will appreciate the energy usage over the whole hour will be approximately 25% higher due to the unloaded running. With a 30KW air compressor this will equate to an additional 7KW for nothing every hour!

Variable speed compressors are an innovation that enables the compressor to rotate more slowly, producing less air, absorbing less energy. In this way the air compressor slows its rotation speed until it is producing exactly that amount of compressed air that is being used by the downstream equipment. It doesn’t need to run unloaded saving significant amounts of energy. On average a variable speed compressor will save 30% of the energy used by a fixed speed compressor, this is particularly true when the compressor isn’t running permanently at full load.

So why isn’t every compressor sold a variable speed compressor? The main reason that fixed speed compressors are still sold is that they are considerably cheaper than variable speed units. Also, at smaller sizes (less than 10KW), the energy saved over the life of the compressor isn’t enough to warrant the additional spend required to get a variable speed unit.

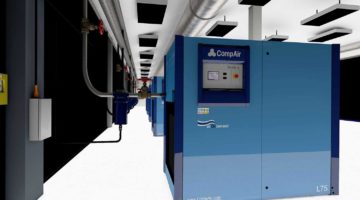

For larger compressed air systems with multiple air compressors and backup air compressors we recommend having a mix of fixed and variable speed air compressors, with a control system to manage the start up of the various compressors to give maximum efficiency of the whole system.

Always Provide a Professional Service...5 Star Rating Always provide a professional service for planned visits and the response time on call outs and breakdowns is superb. Recommendation from a customer in Bedfordshire...

What are the benefits of variable speed compressors?

Professional support when you need it

Air Equipment can support you and your compressed air system throughout its life. We will monitor your system to ensure it remains reliable, efficient and operating correctly. We will service your compressors, filters and air dryers to schedule, to ensure they continue to operate correctly. We can also help and guide you through changes to your air system as your company changes and grows.

Learn about usSign up to the free newsletter and receive our monthly bulletin.