Hot water heat recovery – basic process

Your compressor creates a lot of heat as part of the compression process. Typically over 80% of the energy used in the compression process is given off as heat. For an 11KW compressor this means about 9KW of the input energy is given off as heat, this heat is usually released to the atmosphere and wasted.

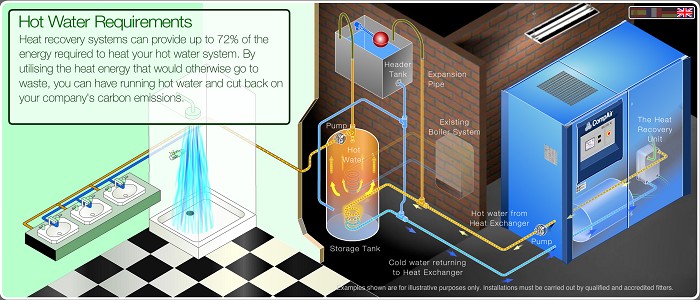

The basic process of hot water heat recovery is to simply add a basic oil/water heat exchanger into the oil cooling circuit of the compressor. Cold water is then passed through the heat exchanger on the way to the boiler. The compressor waste heat is then used to pre-heat the water rather than exhaust it to atmosphere. The warmer water then reduces the work the boiler has to do. When the compressor isn’t running the boiler works as normal (heating the water from cold), and if there isn’t the demand for warm water the compressor cools as normal using its internal cooler.

How much energy can be saved?

How much can you expect to save using hot water heat recovery? Approximately 90% of the energy put into a compressor is given off as heat. So a 22KW compressor is putting out about say 20KW of heat. With the high efficiencies of modern heat exchangers over 90% of this can be captured in the water so for a 22KW compressor you probably can capture 18KW of energy in the water.

What restrictions are there?

There are some restrictions on using this technique. Obviously the costs associated with install of the system means that payback on small compressors is probably not worth the spend. Here I mean anything less than a 15KW compressor may be marginal. If the compressor is in building A and the hot water system in building B half a mile away, the costs of pipework and losses associated with the distance probably also make it a non starter. The heat from the compressor will tend to keep the temperature rise to around 30’C. Compressors are designed to operate at relatively low temperatures, the maximum temperature seen anywhere in a compressor will be around 120’C. The reality is this restricts the ultimate water temperature to around 50- 60’C.